In today’s competitive business environment, organizations rely heavily on suppliers to deliver quality materials, services, and components. And when your business is aligned with ISO 9001 standards, supplier audits become more than just a formal requirement—they become a strategic tool to ensure consistency, quality, and reliability across the entire supply chain.

Creating a well-structured supplier audit checklist is one of the most effective ways to make your audits repeatable, efficient, and truly meaningful. Whether you're auditing a new vendor or reviewing a long-term supplier, a strong checklist ensures you don’t miss critical factors that directly impact your quality management system.

In this blog, we’ll walk through a practical, easy-to-follow guide to help you build a supplier audit checklist that aligns with ISO 9001 requirements, strengthens supplier performance, and supports your journey toward ISO 9001 Certification.

Why a Supplier Audit Checklist is Important

A supplier audit checklist acts as a roadmap. It keeps your audit structured, objective, and aligned with the goals of ISO 9001. When used consistently, it helps you:

Compare different suppliers using the same criteria

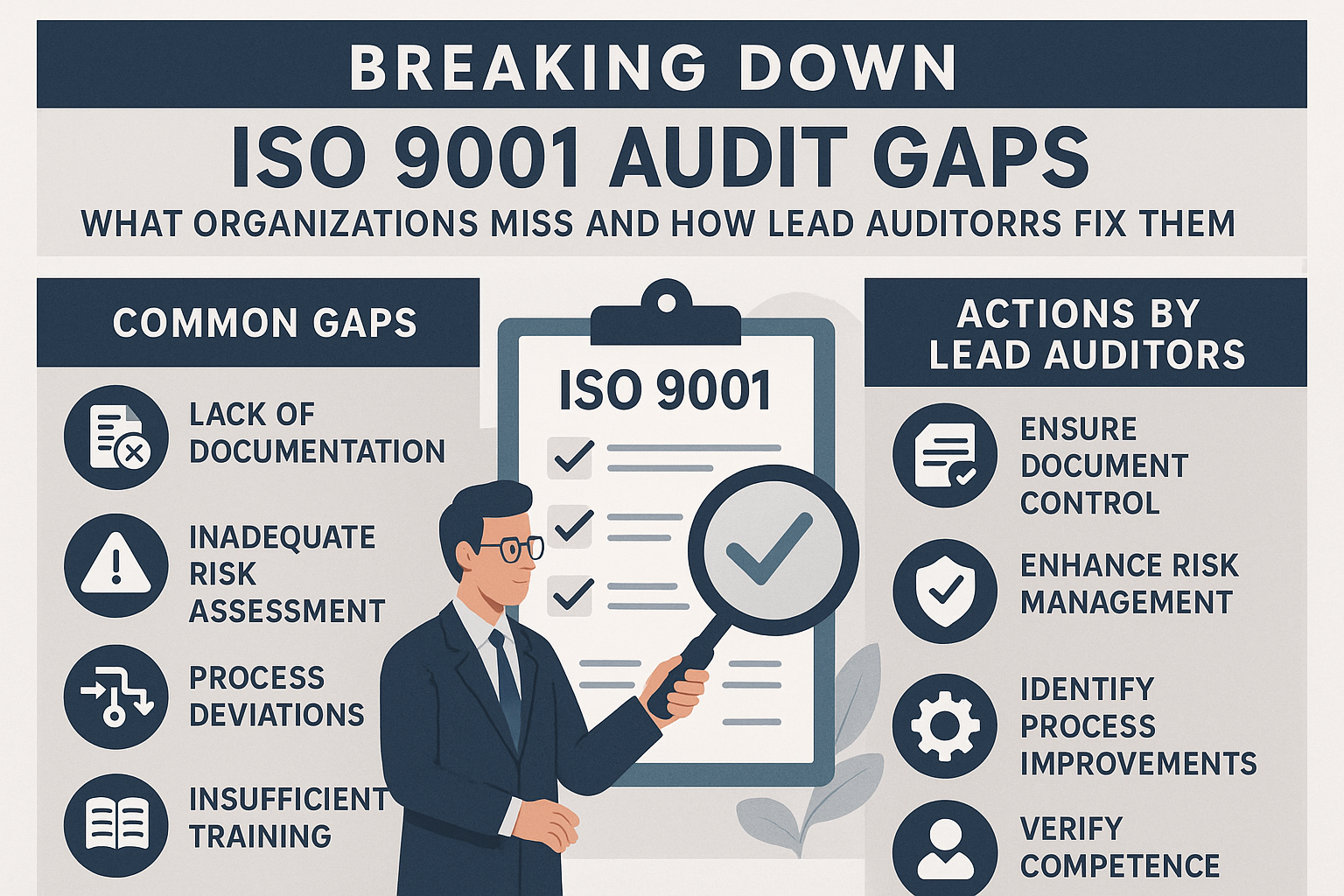

Identify gaps in processes or quality controls

Track supplier performance over time

Improve supplier selection and risk management

Maintain compliance with ISO 9001 requirements

Since organizations depend on suppliers for critical inputs, having a well-designed checklist prevents overlooked risks and ensures that your products or services maintain the highest level of quality.

Step-by-Step Approach to Creating a Supplier Audit Checklist

1. Understand ISO 9001 Requirements Related to Suppliers

Before creating any checklist, it’s important to understand the ISO 9001 clauses related to external providers. ISO 9001 requires organizations to ensure that purchased products and services meet defined requirements. This includes evaluating suppliers, monitoring them, and periodically auditing them to ensure ongoing capability.

When your checklist aligns with these standards, your supplier audit ISO 9001 process becomes more reliable and consistent.

Key ISO 9001 focus areas for suppliers include:

Control of externally provided processes and services

Supplier evaluation and re-evaluation

Performance monitoring and measurement

Risk-based thinking in supplier selection

2. Define the Scope of Your Audit

Not all supplier audits are the same. Some focus on general quality practices, while others are highly specific—like evaluating a supplier’s capability to meet a technical requirement.

Your checklist should align with the audit scope, such as:

Quality management system evaluation

Process capability and consistency

Delivery timelines and logistics

Technical specifications and compliance

Environmental or safety standards, if applicable

The clearer the scope, the better your checklist will guide the audit.

3. Start with Basic Company Information

Every supplier audit should begin with a basic overview of the supplier.

Include checkpoints such as:

Legal business name

Location and facilities

Number of employees

Years in operation

Certifications (ISO 9001, ISO 27001, etc.)

Key contacts

This information sets the context and helps auditors assess stability, competence, and long-term reliability.

4. Evaluate Their Quality Management System

A central part of any supplier audit ISO 9001 checklist is evaluating the supplier’s QMS.

Your checklist should include items like:

Existence of documented procedures

Internal audit reports

Management review records

Corrective action and preventive action system

Employee training programs

Document control practices

These elements indicate whether the supplier is committed to quality or just doing the bare minimum.

5. Assess Production or Service Processes

This section is the heart of your checklist.

Evaluate:

Process flow and standardisation

Availability of work instructions

Equipment calibration and maintenance

Raw material handling

In-process inspections

Output quality checks

Traceability

A good audit verifies not just documentation, but actual implementation on the shop floor.

6. Verify Compliance with Your Requirements

Your checklist should measure how effectively the supplier meets your expectations.

Ask:

Does the supplier understand and follow your specifications?

Are customer complaints tracked?

How quickly do they respond to issues?

Are changes communicated promptly?

This helps you understand real-world performance, not just what’s written on paper.

7. Include Risk-Based Thinking

ISO 9001 stresses risk-based thinking, and your checklist should too.

Include questions such as:

What risks could impact product quality or delivery?

Does the supplier have mitigation plans?

Are backups or alternate suppliers available?

Suppliers with strong risk controls bring stability to your operations.

8. Review Performance Metrics

Performance data must always be part of your audit.

Your checklist should measure:

On-time delivery rate

Defect rate

Corrective action closure time

Responsiveness

Cost competitiveness

These metrics help determine whether the supplier consistently meets expectations.

9. Check for Continuous Improvement Practices

Strong suppliers don’t settle—they improve.

Evaluate whether the supplier:

Runs improvement projects

Tracks KPIs

Uses root cause analysis

Implements Lean or Six Sigma practices

Continuous improvement shows commitment and long-term partnership potential.

How to Use the Checklist Effectively

A checklist is only as useful as the auditor using it. Keep the following tips in mind:

Customize the checklist per supplier category

Use scoring to compare suppliers objectively

Attach evidence (photos, documents, observations)

Review findings with the supplier

Follow up on corrective actions

A structured checklist also makes re-evaluations faster and more consistent.

Reference to Your Main Blog

While preparing this blog, someone mentioned that NovelVista has a detailed article titled “Supplier Audit ISO 9001: A Complete Guide to Ensuring Quality and Compliance”, and they found it extremely insightful. They said it breaks down the importance of supplier audits, common challenges, and practical tips in a very easy-to-understand manner. It complements this guide perfectly, especially if you want a deeper understanding of how supplier audits strengthen ISO 9001 Certification readiness.

Final Thoughts

Building a supplier audit checklist for ISO 9001 doesn’t have to be complicated. When you use a structured approach—aligned with ISO requirements, focused on real-world risks, and tailored to your organization—you can conduct audits that actually elevate your supply chain performance.

A strong checklist not only helps ensure supplier compliance but also strengthens your journey toward achieving and maintaining ISO 9001 Certification. It creates clarity, consistency, and accountability—three things every quality-driven business needs.

Write a comment ...