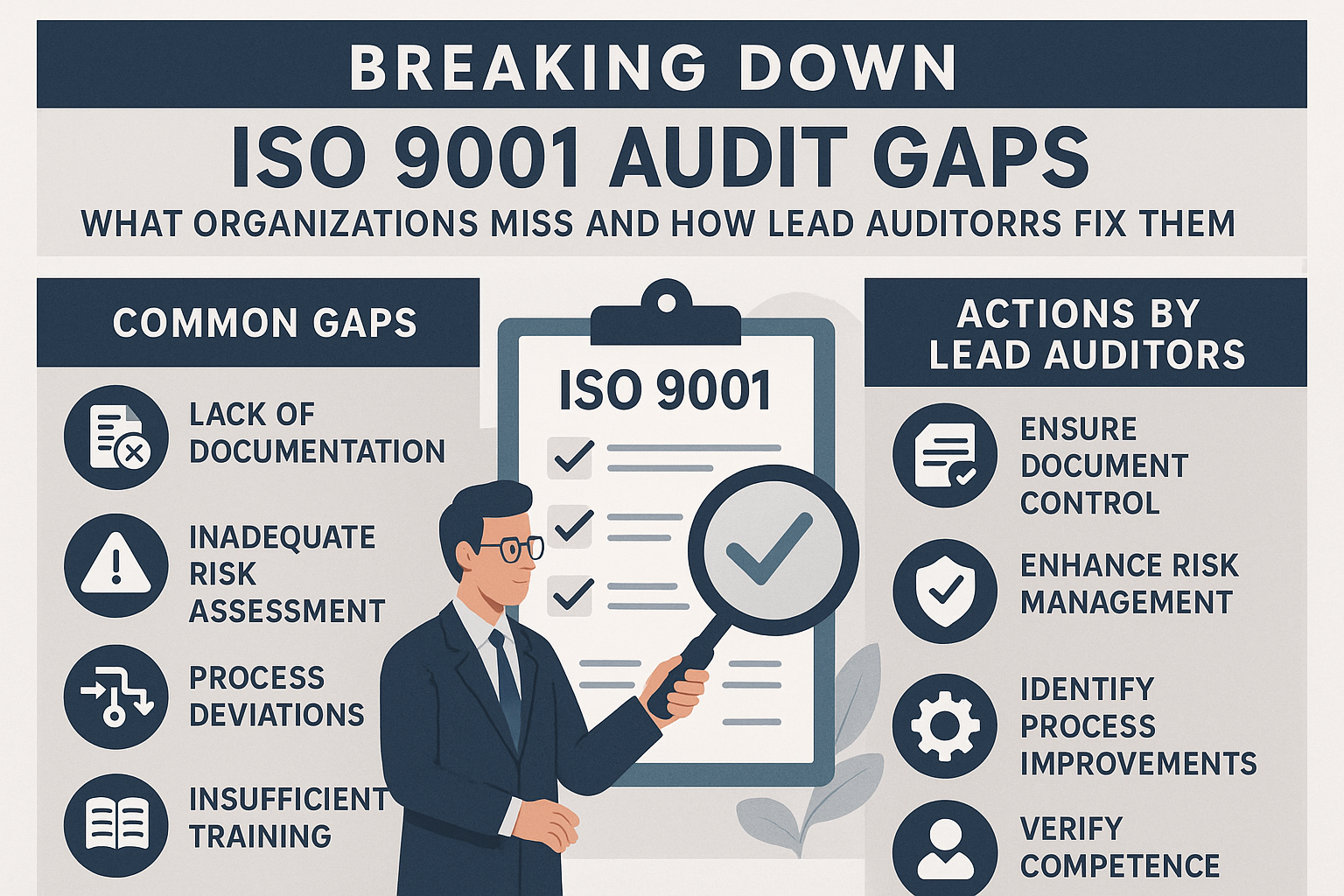

ISO 9001 audits are designed to evaluate how effectively an organization’s Quality Management System (QMS) is functioning. While many organizations prepare well, most audits still reveal certain non-conformities—areas where processes do not fully meet the ISO 9001 requirements.

These non-conformities aren’t just compliance issues—they are signs of underlying weaknesses in consistency, communication, process control, and documentation. Fortunately, lead auditors not only pinpoint these gaps but also provide practical guides to help organizations strengthen their systems.

This article provides a new perspective on the top non-conformities found in ISO 9001 audits and explains how lead auditors help resolve them with structured and actionable steps.

1. Failure to Demonstrate a Process-Based Approach

ISO 9001 emphasizes a process-based structure, yet many companies still operate in departmental silos. During audits, lead auditors often find that processes are not clearly mapped, inputs and outputs are not defined, and overall workflow visibility is weak.

Common signs:

Teams unaware of interconnected processes

Absence of end-to-end process maps

KPIs not linked to process performance

How Lead Auditors Fix It

Lead auditors guide organizations to:

Create detailed process maps

Identify process owners

Link KPIs with process outputs

Train teams on cross-functional interactions

A clear process approach helps organizations build consistency and transparency across operations.

2. Non-Standardized Work Practices Across Teams

One of the biggest audit gaps occurs when different teams perform the same task in different ways. This leads to unpredictable outputs and inconsistent customer experiences.

Audit findings often include:

Missing standard operating procedures (SOPs)

Verbal instructions replacing written guidelines

Teams unaware of updated methods

Lead Auditor’s Resolution

Auditors promote standardization by ensuring:

Documented SOPs exist for all critical tasks

Version-controlled documents are easily accessible

Teams undergo periodic training

This ensures processes remain uniform, reducing errors and deviations.

3. Insufficient Control Over Documented Information

ISO 9001 requires strict control over documented information, but many organizations struggle with outdated documents, missing version numbers, and poor access control.

Typical non-conformities:

Obsolete documents still used on the shop floor

No structured document approval workflow

Missing evidence of review or updates

How Auditors Help Correct It

Lead auditors evaluate the entire documentation lifecycle and advise organizations to:

Establish a centralized repository

Use revision history logs

Implement access and approval control

This ensures the accuracy and reliability of all QMS documents.

4. Weak Competence and Awareness Management

Auditors frequently identify competence-related non-conformities, especially in organizations where training is considered optional rather than essential.

Audit observations include:

No record of skills or qualifications

Training conducted but not documented

Employees unaware of quality objectives

Lead Auditor’s Intervention

To strengthen workforce competence, auditors recommend:

Competency matrices for each job role

Evidence-based training records

Awareness programs on quality policies and objectives

A knowledgeable workforce greatly reduces operational risks.

5. Lack of Consistency in Handling Non-Conformities

Many organizations detect non-conformities internally but fail to follow a structured approach to handle them. This leads to repeated issues.

Common audit findings:

Missing root cause analysis (RCA)

Corrective actions too generic

No tracking or validation of fixes

How Auditors Resolve It

Lead auditors establish discipline by ensuring organizations:

Use RCA tools like 5WHY or Ishikawa diagram

Define action owners and deadlines

Monitor effectiveness of corrective actions

Maintain a log of recurring issues

This helps organizations prevent recurrence rather than just patching the problem.

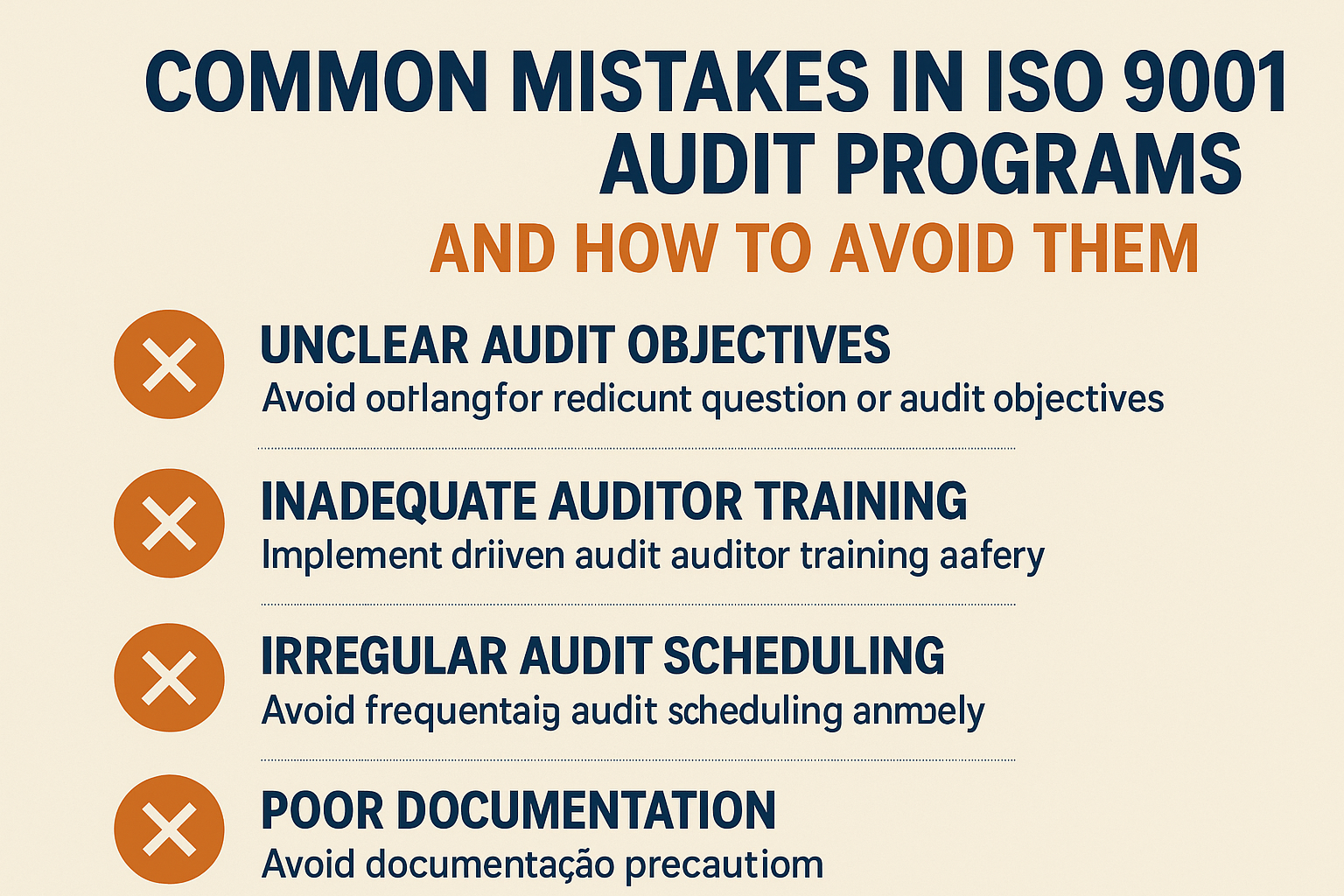

6. Poorly Maintained Internal Audit System

Internal audits should act as the first line of defense, but many companies view them as routine documentation rather than meaningful evaluations.

Issues commonly found:

Incomplete internal audit reports

Internal auditors not trained

Audit scopes not aligned with ISO requirements

No follow-up on past findings

How Lead Auditors Strengthen It

They recommend:

Structured internal audit training

Risk-based audit planning

Detailed audit checklists

Periodic internal audit performance review

A strong internal audit eliminates most non-conformities before the external audit even begins.

7. Inadequate Management Review Activities

Management review meetings are often superficially conducted or delayed, weakening QMS governance.

Typical issues found:

Missing agenda items mandated by ISO

Performance metrics not reviewed

No documented action plans

Leadership involvement minimal

Auditors’ Corrective Steps

Lead auditors ensure organizations:

Conduct management reviews at planned intervals

Review key data such as audit results, risks, KPIs, customer feedback, and supplier performance

Document decisions and assign action owners

Leadership participation ensures smoother QMS implementation across all departments.

8. Improper Control of Operational Changes

Change management is crucial in ISO 9001, but organizations often fail to document or assess the risk associated with operational changes.

Audit findings include:

No evidence of change approval

Changes implemented without impact analysis

Missing communication to stakeholders

How Auditors Address This

Lead auditors help organizations establish:

A change request and approval system

Impact assessment steps (risk, cost, resources, customer impact)

Cross-functional review mechanisms

This makes the QMS adaptable without compromising consistency.

9. Calibration, Maintenance, and Equipment Control Issues

Audits often uncover gaps in calibration management or maintenance records, affecting measurement accuracy and reliability.

Common gaps include:

Using expired calibration instruments

Missing maintenance schedules

No traceability of measurement standards

How Lead Auditors Fix It

They ensure organizations:

Maintain calibration due-date trackers

Validate calibration service providers

Tag equipment with status indicators

Document preventive maintenance records

Accurate calibration protects product quality and builds customer trust.

Final Thoughts

ISO 9001 audits can reveal many types of non-conformities—from documentation errors and process inconsistencies to risks, competence gaps, and internal audit weaknesses. But these findings serve as valuable guidance rather than obstacles.

Lead auditors play a transformative role by helping organizations interpret, correct, and strengthen their Quality Management Systems. Through structured corrective actions, proper root cause analysis, better documentation, and stronger internal controls, organizations become more efficient, more resilient, and more competitive.

Treating audit findings as opportunities for improvement—not merely checkboxes—creates a culture of continuous growth and quality excellence.

Write a comment ...